Heavy duty truck shock absorbers: the core guarantee of efficient transportation

2025.07.08

2025.07.08

Industry News

Industry News

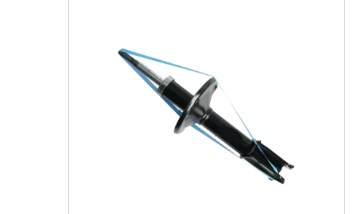

Among the core components of heavy-duty trucks, shock absorbers are often overlooked, but they are like the "spine" of the vehicle, silently supporting stability, safety and economy under complex working conditions. For heavy trucks that travel on mountain roads, mining areas, highways and other diverse scenes all year round, a set of high-performance heavy duty truck shock absorbers can not only reduce driving fatigue caused by bumps, but also reduce vehicle component wear and tear, extend tire life, and even directly affect freight efficiency.

Why are heavy duty truck shock absorbers "very important"?

Unlike passenger cars, heavy trucks often carry tens of tons of load and have complex and changeable driving environments, which puts almost harsh requirements on shock absorbers. Its core function is not simply to "filter vibrations", but to find a precise balance between load capacity and shock absorption effect.

When a heavy truck is fully loaded with goods and travels on a bumpy road, the impact force of the road surface will be transmitted to the body through the tires and suspension. If the shock absorber performance is insufficient, it will not only cause severe bumps in the cab and affect the driver's control, but also cause repeated impacts on the cargo - for special cargo such as precision instruments and fragile items, this impact may directly cause cargo damage. More seriously, long-term high-frequency vibration will aggravate the wear of key components such as the frame, axle, and gearbox, greatly shorten the service life of the vehicle, and increase maintenance costs.

When driving at high speed or emergency braking, heavy duty truck shock absorbers can effectively suppress the "nodding" and "rolling" phenomena of the vehicle body, improve tire grip, and shorten the braking distance. For the freight industry, which relies on "timeliness" and "cost" as its lifeline, the importance of shock absorbers is self-evident.

Core technology analysis of heavy duty truck shock absorbers

Currently, mainstream heavy truck shock absorbers mostly adopt hydraulic structures, which generate damping force through the flow of oil in the piston cavity to achieve the absorption and release of vibration energy. However, to meet the special needs of heavy trucks, in-depth optimization is required in the following technical dimensions:

1. Multi-stage damping adjustment technology

Excellent heavy truck shock absorbers can automatically switch damping modes according to road conditions. For example, on flat high-speed roads, the damping force is small to ensure driving comfort; when encountering bumpy sections, the damping force increases instantly to suppress excessive vibration of the vehicle body.

2. High-strength materials and sealing technology

The working environment of heavy truck shock absorbers is often accompanied by high temperature, dust, mud and water, which puts strict requirements on materials. The piston rod is mostly made of chrome-plated alloy steel, and the surface roughness is controlled below 0.05μm to ensure wear resistance and corrosion resistance; the cylinder barrel is made of high-strength seamless steel pipe, and after quenching treatment, the compressive strength can reach more than 800MPa.

Sealing performance is the "lifeline" of hydraulic shock absorbers. High-quality products use a multi-layer lip seal structure, combined with oil-resistant rubber and metal skeleton, which can prevent oil leakage and ensure stable damping force even at extreme temperatures of -40℃ to 120℃.

3. Adaptability design

Heavy trucks for different purposes have significantly different requirements for shock absorbers: tractor heads focus on cab comfort and steering stability, dump trucks need to strengthen impact resistance when carrying loads, and tank trucks pay more attention to stability during driving to prevent liquid sloshing. Therefore, shock absorbers need to be customized according to vehicle type (traction, cargo, special vehicles, etc.), load range, and common road conditions. For example, shock absorbers for heavy trucks in mining areas will appropriately increase the damping coefficient to cope with high-frequency impacts; for long-distance trunk tractor heads, low-speed damping will be optimized to improve driving smoothness.

How to choose the right shock absorber for your heavy truck?

When purchasing shock absorbers for heavy trucks, it is not advisable to blindly pursue "high-end" or "low-price". It is necessary to make a comprehensive judgment based on the actual working conditions:

1. Clarify the purpose and working conditions of the vehicle

Long-distance high-speed trunk lines: give priority to shock absorbers with electronic adjustment functions, taking into account both comfort and high-speed stability;

Mining areas, construction sites and other non-paved roads: focus on high-strength and wear-resistant models, and give priority to products with a large adjustable damping force range;

Urban distribution or light-load transportation: You can choose standard shock absorbers with higher cost performance, but you need to ensure that the sealing performance meets the standards.

2. Focus on core parameters

Damping coefficient: The larger the value, the stronger the "rigidity" of the shock absorber, which is suitable for heavy loads or bumpy roads; too small a value may cause the body to shake, and it needs to be matched according to the load range;

Operating temperature range: In cold northern regions, products with strong low-temperature adaptability should be selected (still able to work normally below -30°C), and in hot southern environments, attention should be paid to high-temperature stability;

Life index: The design life of high-quality shock absorbers should not be less than 300,000 kilometers. When purchasing, you can refer to the fatigue test report provided by the brand.

3. Beware of "pseudo-professional" traps

Some small factory products claim "ultra-high pressure design" and "lifetime maintenance-free", but in fact there are safety hazards. For example, excessive pursuit of high pressure may cause the shock absorber to be too rigid and lose its buffering effect; while "maintenance-free" often means a simplified sealing structure, which may perform well in the short term, but is prone to oil leakage and failure in long-term use. It is recommended to choose brands with OEM supporting qualifications (such as Vibraco, Sachs, Zhengyu Industry, etc.), whose products have undergone rigorous bench testing and actual vehicle verification, and the quality is more guaranteed.

In today's increasingly competitive freight industry, the optimization of every detail may become the key to success. Pay attention to the value of shock absorbers to make vehicles more stable, more economical and safer while transporting efficiently.

EN

EN  English

English Español

Español

+86-13757453333

+86-13757453333  +86-572-8355557

+86-572-8355557  Caroline@gerep.cn

Caroline@gerep.cn  No. 36, South Zhenxing Rd., Zhongguan Town, Deqing County, Huzhou, Zhejiang, China

No. 36, South Zhenxing Rd., Zhongguan Town, Deqing County, Huzhou, Zhejiang, China