How to Choose Heavy-Duty Truck Shock Absorbers? What Factors Determine Their Performance?

2026.01.22

2026.01.22

Industry News

Industry News

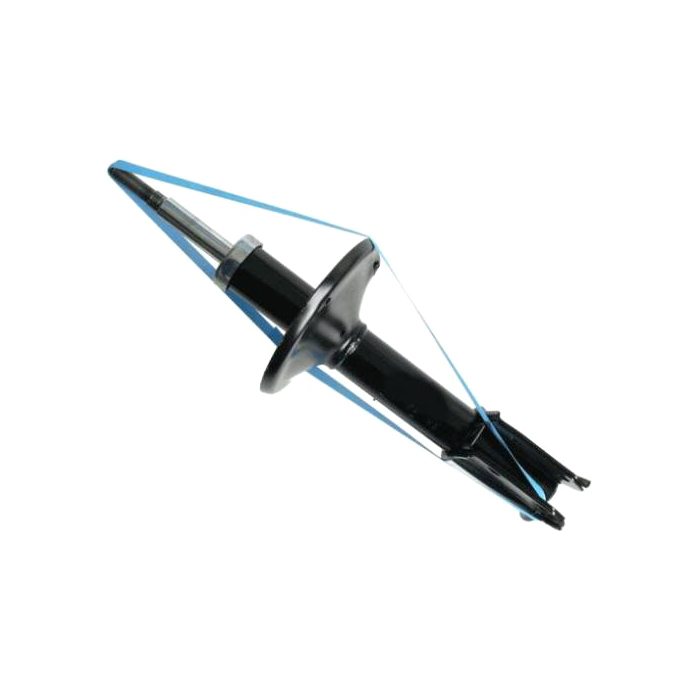

In the design and maintenance of heavy-duty trucks, shock absorbers, as a crucial component of the suspension system, play a vital role in improving vehicle stability, safety, and comfort. Whether on highways or rough mountain roads, shock absorbers effectively reduce the impact force from uneven road surfaces, ensuring the safety of both the driver and the cargo.

I. Basic Working Principle of Heavy-Duty Truck Shock Absorbers

Shock absorbers are devices used to absorb and reduce impact forces from the road surface. They are mainly composed of components such as gas, liquid, or springs, and suppress body vibration through different design principles. In heavy-duty trucks, the task of shock absorbers is particularly demanding because heavy-duty trucks carry heavy loads, and the vibrations and impact forces generated during driving are relatively strong.

When a truck is driving, the friction between the tires and the ground constantly changes, especially when encountering potholes and uneven road surfaces, causing the vehicle body to shake violently up and down. At this time, the shock absorber absorbs this vibration energy through liquid flow or gas compression, thereby reducing body vibration. In this way, the shock absorber not only improves the comfort of the vehicle but also effectively reduces wear and tear on the vehicle body.

II. Types and Characteristics of Heavy-Duty Truck Shock Absorbers

Based on design principles and functional requirements, heavy-duty truck shock absorbers can be divided into several different types, including hydraulic shock absorbers, pneumatic shock absorbers, and electronically controlled shock absorbers. Each type of shock absorber has its unique advantages and applicable scenarios.

Hydraulic Shock Absorbers

Hydraulic shock absorbers utilize the fluidity of liquid to absorb impact forces and are commonly used in most traditional heavy-duty trucks. These shock absorbers usually have high durability and stability, maintaining good damping effects over long periods of use. However, hydraulic shock absorbers are relatively sensitive to temperature changes; extremely high or low temperatures may affect their performance.

Pneumatic Shock Absorbers

Pneumatic shock absorbers absorb vibrations by compressing gas, offering better adaptability and stability. Compared to hydraulic shock absorbers, pneumatic shock absorbers perform more stably under temperature changes and provide a softer damping effect, making them particularly suitable for heavy-duty trucks used in long-distance transportation.

Electronically Controlled Shock Absorbers

Electronically controlled shock absorbers are a relatively new technology that uses an electronic control system to adjust the stiffness and damping force of the shock absorber in real time, ensuring optimal damping performance under different operating conditions. These shock absorbers can automatically adapt to different road conditions, improving driving comfort and vehicle safety.

III. Factors to Consider When Choosing Heavy-Duty Truck Shock Absorbers

When choosing heavy-duty truck shock absorbers, in addition to understanding the types of shock absorbers, several key factors need to be considered to ensure that the selected shock absorbers meet the truck's performance requirements.

Vehicle Load Capacity

Different heavy-duty trucks have different load capacities and force requirements depending on their transportation tasks. When choosing shock absorbers, it is necessary to select the appropriate type and stiffness based on the truck's total load capacity. If the shock absorber's load capacity is insufficient, it may not effectively absorb vibrations, affecting vehicle stability and safety.

Driving Environment and Road Conditions

Different driving environments have different requirements for shock absorbers. For example, heavy-duty trucks driving on highways usually require relatively stable shock absorbers to ensure body stability. Heavy-duty trucks driving on rough mountain roads or construction roads require shock absorbers with higher damping performance to cope with frequent bumps.

Durability and Maintenance Costs of Shock Absorbers

As an important automotive part, the durability of shock absorbers is crucial for the long-term operation of heavy-duty trucks. Choosing shock absorbers with strong wear resistance and a long service life can not only reduce maintenance frequency but also lower the overall operating costs of the vehicle. High-quality shock absorbers usually require less maintenance and maintain stable performance over a long period.

Comfort and Safety

Although the comfort requirements for heavy-duty trucks are not as high as those for passenger cars, comfort is still an important factor in whether drivers can drive safely for extended periods. A high-quality shock absorber can effectively reduce driver fatigue, improve vehicle handling, and enhance driving safety.

IV. How to Determine if Heavy-Duty Truck Shock Absorbers Need Replacement?

Over time, heavy-duty truck shock absorbers will gradually age or wear out, leading to a decrease in damping effect. To maintain the truck's performance and safety, regular inspection of the shock absorbers' condition is very important. Vehicle instability: If the truck experiences abnormal shaking or vibration during driving, especially on bumpy roads, it may indicate a decrease in shock absorber performance.

Wheel bouncing: If the shock absorbers are malfunctioning, the wheels may bounce during driving, which is particularly noticeable during acceleration or braking.

Shock absorber oil leakage: Oil leakage from the shock absorber usually means that its internal seals are damaged, affecting the damping effect and requiring prompt replacement.

V. FAQ: Frequently Asked Questions about Heavy Truck Shock Absorbers

1. How long is the service life of heavy truck shock absorbers?

The service life of heavy truck shock absorbers is affected by various factors, such as driving environment, load conditions, and the material of the shock absorbers. Generally, hydraulic shock absorbers have a lifespan of about 50,000 kilometers, while pneumatic and electronically controlled shock absorbers can last longer, reaching 70,000 to 100,000 kilometers. Regular inspection and maintenance of shock absorbers can effectively extend their service life.

2. Can I replace heavy truck shock absorbers myself?

Although replacing shock absorbers is not a complicated task, considering safety and technical requirements, it is recommended that the replacement be performed by professional automotive repair personnel. Improper installation due to self-replacement may affect the vehicle's driving performance and safety.

3. Should heavy truck shock absorbers be replaced or repaired when they malfunction?

If the shock absorber has minor damage, such as oil leakage or slight wear, repair or refilling may be considered. However, if the shock absorber's performance is severely degraded and cannot effectively absorb vibrations, it is recommended to replace it with a new one to ensure the vehicle's driving safety.

4. How to choose the right shock absorber brand for my truck?

When choosing shock absorbers, it is recommended to choose products from well-known brands. These brands usually provide higher quality shock absorbers and have a more comprehensive after-sales service system. In addition to the brand, you also need to choose the appropriate shock absorber based on your truck model, operating environment, and load requirements.

EN

EN  English

English Español

Español

+86-13757453333

+86-13757453333  +86-572-8355557

+86-572-8355557  Caroline@gerep.cn

Caroline@gerep.cn  No. 36, South Zhenxing Rd., Zhongguan Town, Deqing County, Huzhou, Zhejiang, China

No. 36, South Zhenxing Rd., Zhongguan Town, Deqing County, Huzhou, Zhejiang, China