In the design and maintenance of heavy-duty trucks, shock absorbers, as a crucial component of the suspension system, play a vital role in improving vehicle stability, safety, and comfort. Whether on highways or rough mo...

READ MORE-

-

Peace be upon you. ZHEJIANG GEREP AUTOMOTIVE PARTS MFG.CO., LTD., a leading manufacturer of shock absorbers in China, is proud to announce its participation in the upcoming 2026 Saudi Arabia Auto Parts Exhibition in Riya...

READ MORE -

In modern cars, the suspension system and shock absorbers play a crucial role in ensuring vehicle stability and comfort. The rear shock absorbers, in particular, not only directly affect the smoothness of the driving exp...

READ MORE

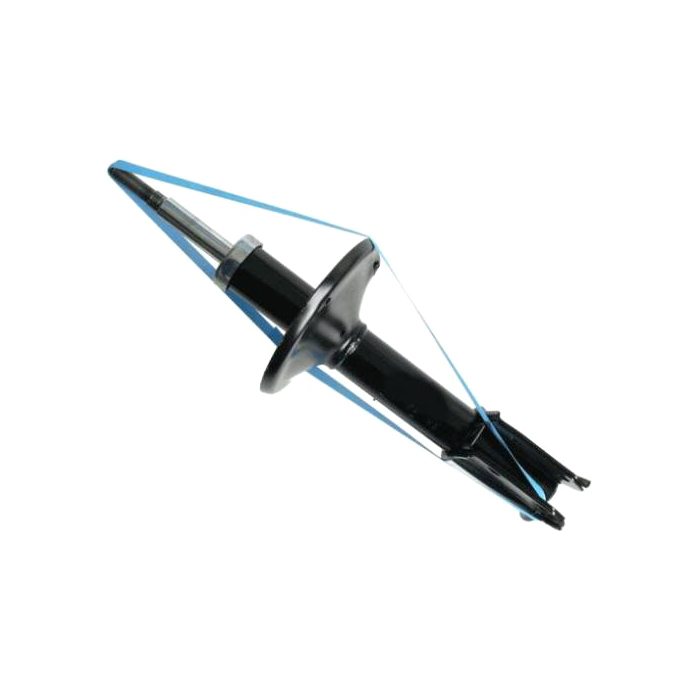

What is the surface treatment process of Dacia passenger car shock absorbers?

GEREP has a strong team of more than 50 professional technicians, 10 senior engineers and 20 QA inspectors. Such a team configuration ensures that every link from R&D to production to sales can reach the industry-leading level. In order to continuously improve product quality and technical level, GEREP introduced advanced production equipment from Germany and established its own high-precision machining center, mold development center, new product development center and testing center. These centers not only provide strong technical support for the innovative design of products, but also provide a solid foundation for the research and development and optimization of shock absorber surface treatment technology.

As an important part of the automobile suspension system, the performance of the shock absorber directly affects the vehicle's handling, ride comfort and safety. The surface treatment process of the shock absorber is the key to ensure its long-term stable operation and resistance to harsh environments and corrosion. Good surface treatment can not only improve the durability of the shock absorber, but also reduce friction and noise, thereby improving the performance of the entire vehicle.

In response to the specific needs of Dacia passenger car shock absorbers, GEREP uses the following advanced surface treatment processes:

Sandblasting: As a pretreatment step, sandblasting can remove oil, rust and old coatings on the surface of the shock absorber, increase the surface roughness, and provide a good adhesion foundation for subsequent painting. GEREP uses efficient and environmentally friendly sandblasting equipment to ensure that the treatment process is uniform, efficient and environmentally friendly.

Zinc phosphating treatment: After sandblasting, the shock absorber will enter the zinc phosphating solution for phosphating. This step can form a dense phosphating film on the surface of the shock absorber. The film has good anti-corrosion performance and adhesion, providing an ideal base for subsequent electrophoretic coating. GEREP's phosphating treatment process has been carefully optimized to ensure that the film layer is uniform and dense, effectively improving the corrosion resistance of the shock absorber.

Electrophoretic coating: Electrophoretic coating is an efficient and environmentally friendly coating method. It uses the action of an electric field to make the paint particles deposit on the surface of the shock absorber in a directional manner to form a uniform and continuous coating film. GEREP's electrophoretic coating line is equipped with advanced automation equipment and intelligent control systems, which can accurately control the coating parameters to ensure that the thickness, uniformity and gloss of the coating film are in the best state. Electrophoretic coating not only improves the appearance quality of the shock absorber, but also significantly enhances its anti-corrosion performance.

Powder spraying: In certain specific cases, in order to further improve the weather resistance and decorativeness of the shock absorber, GEREP also uses powder spraying technology. Powder coating has the advantages of no pollution, high efficiency, easy recycling, and strong adhesion, high hardness and good wear resistance after spraying. Through precise spraying control and high-temperature curing treatment, GEREP can ensure that the powder coating is tightly combined with the surface of the shock absorber to form a solid protective layer.

Quality inspection and control: During the entire surface treatment process, GEREP's QA inspectors will conduct strict quality inspection and control of each process. From the entry of raw materials to the exit of finished products, every link has undergone strict inspection and testing to ensure that the surface treatment quality of the shock absorber meets international standards and customer requirements.

GEREP's advantages

Technology leadership: GEREP constantly adopts new materials and new designs to ensure that the surface treatment process of shock absorbers is always at the forefront of the industry.

Advanced equipment: Advanced production equipment introduced from Germany provides efficient and precise processing capabilities for shock absorber surface treatment.

Reliable quality: Strict quality management system and QA inspection process ensure the consistency and stability of the quality of shock absorber surface treatment.

Thoughtful service: GEREP not only provides high-quality shock absorber products, but also provides a full range of pre-sales, in-sales and after-sales services to meet the diverse needs of customers.

EN

EN  English

English Español

Español

+86-13757453333

+86-13757453333  +86-572-8355557

+86-572-8355557  Caroline@gerep.cn

Caroline@gerep.cn  No. 36, South Zhenxing Rd., Zhongguan Town, Deqing County, Huzhou, Zhejiang, China

No. 36, South Zhenxing Rd., Zhongguan Town, Deqing County, Huzhou, Zhejiang, China