How does Automotive Suspension Europe enhance vehicle handling and comfort?

2025.12.08

2025.12.08

Industry News

Industry News

In the modern automotive industry, the suspension system not only determines a vehicle's handling and comfort but also directly impacts driving safety and overall performance. Automotive Suspension Europe's development and innovation set an industry benchmark.

The Basic Principles and European Characteristics of Automotive Suspension Systems

The core function of an automotive suspension system is to support the vehicle body, absorb road impacts, and maintain optimal tire-to-ground contact. European automotive suspension systems prioritize dynamic balance and comfort in their design, employing advanced mechanical simulation and road simulation technologies. Through precise tuning of spring stiffness and damping characteristics, they achieve vehicle stability and handling response under various road conditions.

Compared to traditional designs, European suspension systems place greater emphasis on a balanced driving experience. Whether in luxury sedans or compact models, the suspension systems undergo rigorous multi-dimensional testing to ensure continuous and uniform force feedback during high-speed cornering, braking, and acceleration. This design philosophy reflects Europe's profound understanding of the driving experience—finding the optimal balance between safety and comfort.

Structural Design and Technological Innovation

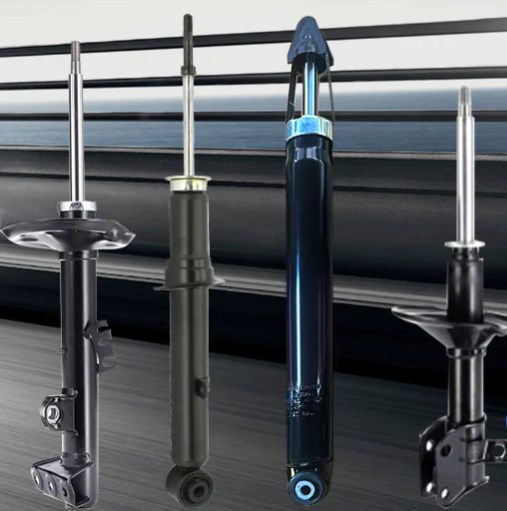

At the structural level, European automotive suspension systems demonstrate a high degree of technological maturity. Common independent suspension designs optimize tire trajectory through MacPherson struts, double wishbones, or multi-link configurations, improving tire grip and steering precision. Especially in multi-link suspensions, the precise calculation of the geometry of each control arm effectively reduces body roll and body vibration, enhancing handling stability.

Meanwhile, electronically controlled suspension technologies (such as active hydraulic damping systems and air suspension systems) are widely used in high-end European models. These systems automatically adjust suspension stiffness by sensing vehicle speed, road conditions, and driving mode in real time, ensuring optimal performance under various driving conditions. This not only improves driving safety but also gives the vehicle high adaptability, meeting consumers' dual demands for comfort and sportiness.

Professional Optimization of Materials and Manufacturing Processes

Automotive Suspension Europe is extremely particular about material selection, primarily using high-strength steel, aluminum alloys, and composite materials to balance strength, toughness, and lightweight requirements. Lightweight design not only reduces overall vehicle weight but also improves fuel economy and handling performance. Furthermore, the application of precision heat treatment and surface strengthening processes ensures that suspension components maintain reliability and durability even under high stress and prolonged vibration.

In terms of manufacturing processes, European production lines generally employ advanced automated processing and testing equipment, with each suspension component undergoing rigorous dimensional control and performance verification. Especially critical connection points, such as ball joints, bushings, and shock absorber interfaces, are all machined with high precision to ensure assembly accuracy and long-term stability. This strict control over the product itself puts European suspension systems at the forefront of the industry in terms of durability and performance.

Performance Tuning and Driving Experience Optimization

Suspension system tuning is a crucial factor in determining the driving experience. European automakers typically optimize spring stiffness, damping coefficient, geometry, and air suspension pressure through comprehensive vehicle dynamics analysis and real-world road testing, achieving a balance between smoothness and handling under various operating conditions. Tuning not only focuses on high-speed stability but also considers low-speed comfort and refined road feedback.

Many European models offer adjustable suspension systems, allowing drivers to select different modes according to road conditions or personal preferences. This personalized tuning approach makes the suspension system not only a safety guarantee but also a core technology for enhancing driving pleasure. The vehicle's support in corners, stability during straight-line acceleration, and shock absorption comfort are all optimized through precise tuning.

Sustainability and Environmentally Friendly Design

With increasingly stringent environmental requirements, European automotive suspension systems also have significant advantages in material recycling and environmentally friendly manufacturing. High-performance alloys and composite materials not only ensure mechanical performance but also reduce energy and resource consumption during the manufacturing process. Some shock absorbers and spring systems also feature recyclable designs, effectively reducing environmental impact at the end of the product's life cycle. This product design philosophy not only reflects technological advancement but also meets the high standards of sustainable development in the European market.

European automotive suspension systems, with their precise design, optimized materials, advanced manufacturing processes, and excellent performance tuning, have become a benchmark in the global automotive industry. Whether in safety, comfort, or handling performance, these systems demonstrate the inherent value of the product. For consumers seeking a high-quality driving experience, the European suspension system is not just a technological feature but also a crucial support for the overall vehicle performance.

FAQ

Q: What is the biggest difference between a European suspension system and a conventional suspension system?

A: European suspension systems prioritize overall balance and driving experience. Through precise design and tuning, they achieve a balance between comfort and handling, while extensively utilizing advanced materials and electronic control technology to ensure high reliability and durability.

Q: What are the advantages of electronically controlled suspension systems in European vehicles?

A: Electronically controlled suspensions can adjust damping and stiffness in real time according to vehicle conditions, maintaining optimal performance under different road conditions, improving safety, and providing a personalized driving experience.

Q: What are the characteristics of European suspension systems in terms of material selection?

A: They use high-strength steel, aluminum alloys, and composite materials to ensure lightweight, durability, and high strength, combined with precision heat treatment and surface strengthening processes to improve component durability.

Q: How important is suspension system tuning to the driving experience?

A: Tuning determines the vehicle's stability, comfort, and handling at high and low speeds, affecting the overall dynamic performance of the vehicle and is a core element in enhancing the driving experience.

EN

EN  English

English Español

Español

+86-13757453333

+86-13757453333  +86-572-8355557

+86-572-8355557  Caroline@gerep.cn

Caroline@gerep.cn  No. 36, South Zhenxing Rd., Zhongguan Town, Deqing County, Huzhou, Zhejiang, China

No. 36, South Zhenxing Rd., Zhongguan Town, Deqing County, Huzhou, Zhejiang, China